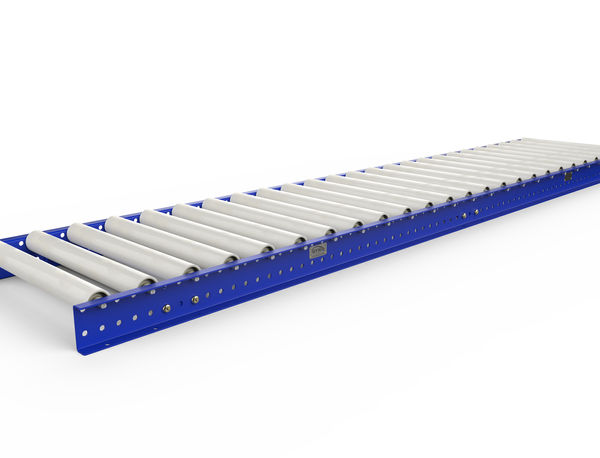

Roller Conveyors

What is a Roller Conveyor?

Roller conveyors are a selection of rollers held together by a supporting structure that allows any object to be moved easily. Depending on user requirements, roller conveyors make moving objects far easier and can be moved physically (e.g. by hand), placed at an incline allowing gravity to do the work, or electronically if you require something with a little more power.

Roller conveyors are extremely flexible pieces of kit that come in various different options to ensure they meet the requirements and can easily work with existing conveyor systems. They can be produced as a straight running roller or if something a little more bespoke is required such as a bend or snake, these adaptable conveyors can add some great versatility to any production line.

See a Roller Conveyor in action (video)...

What are the different types of roller conveyors?

Powered Roller Conveyor or Lineshaft Roller Conveyor

These are the most adaptable & most cost effective types of roller conveyor.

Typically powered via a motor gearbox that conveys drive through a line shaft and a selection of small endless bands providing a continuous rotation on the roller shafts.

Motorised Roller Conveyor

A motorised roller conveyor is designed to allow separate zones within the network to be independently managed and to generate drive only when they are required to do so. There are a number of different reasons for choosing a motorised roller conveyor including reduced energy usage and consumption, quieter noise levels & improved life span of the roller conveyor & system parts.

The ability to stop and start on command is automated and is controlled by sensors opposite each roller drive. Products can be held within zones, and wait for the next zone to clear if required preventing pressure on lines which can have additional repercussions.

Gravity Roller Conveyor

Gravity roller conveyors tend to be the most cost effective type of conveyor. There’s no requirement for a power source and uses the power of nature to move items from one area to another. With a slight push the items can be on their way.

Typically they are lightweight and come in a variety of shapes and sizes to fit into an existing system or can be created bespoke to suit specific requirements. Should the conveyor be required in lots of different locations, or if it needs moving during different times in production, they can be fitted with castors to be moved around easily and without any heavy lifting.

What industries use roller conveyors?

Roller conveyors are great within most industries and can be used within most production lines. Most popular industries are listed below;

-

End of production packaging areas

-

Postage or mail delivery services

-

Airport & baggage handling

-

Glass or large / wide item production or manufacturing

-

Steel manufacturing

Photos of Roller Conveyors

24 / 7 Emergency Support

We're available for emergency call outs and fitting if you experience a breakdown or conveyor belt failure. We pride ourselves on our speed and reliability, and offer same day conveyor belt production and fitting if required.

For general enquiries, please contact any member of our servicing team on the below contact details;

Contact Us

Phone: 01772 439 088

Email: support@rdsupply.co.uk